These gemstones are usually thought to have a deep blue coloration, but sapphires can actually be found in many different colors. Trace amounts of other elements, like chromium, copper, magnesium, iron, and titanium, can give the stones yellow, purple, orange, or green coloration instead. Read More…

LSP Industrial Ceramics is a manufacturing and stocking distributor of both technical and industrial ceramics. We carry a vast inventory of tubes, scrapers, bushings, and other products. We also offer custom parts. With access to our unfired materials, we can assure that LSP Industrial has the flexibility to supply you with the part you need. Because we have our own inventory of materials...

Insaco provides custom grinding and machining services to fabricate precision parts from sapphire, quartz, and most technical ceramics including alumina, zirconia, silicon carbide, silicon nitride, aluminum nitride, and others. Engineers are available to discuss material options/alternative recommendations, as well as design concepts to help our customers minimize fabrication costs. Since 1947...

Years of experience have created unique specializations and expertise of our engineering and product consultation team. Applied Ceramics has a proven track record in creating the highest quality products for semiconductor processing equipment, automotive ceramics, cutting tools and many other industrial ceramics. We’ve machined products for industries such as aerospace/aviation, medical,...

More Sapphire Machining Manufacturers

Chromium impurities give sapphires a red tint, and these sapphires are usually called rubies. Sapphires can be mined in many locations around the world, including Thailand, China, Madagascar, North America, and East Africa.

However, sapphires can also be created synthetically. The ability to manufacture sapphires has made this material more available for use in industrial and scientific applications.

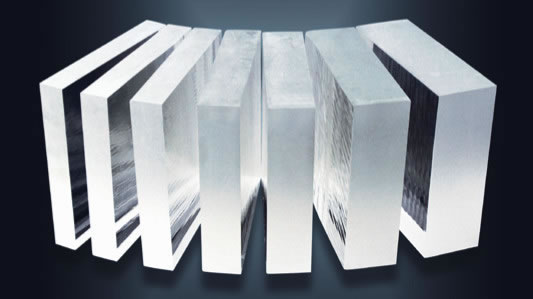

Industrial sapphire is made by melting aluminum oxide and then promoting crystal growth with a seed and by carefully controlling the environmental factors. Different seed materials and environmental factors result in varying sizes, qualities, costs, and shapes.

These shapes can include ribbons, tubes, or rod-like boules which are then machined into more easily employed sizes and shapes. The material does tend to chip somewhat easier than alumina, but applying the correct grinding procedure and technique will easily avoid this.

Sapphires have several important qualities that make them especially useful in industrial settings. For example, sapphires exhibit a hardness of 9 on the Mohs scale, which makes it the third hardest mineral.

It is also birefringent, an “optical refractive property which offsets wave transmission up to 0.8% at right angles to the optic axis.” Therefore, this mineral is commonly used in optical components, like lasers, in durable, shatter resistant glasses, and in substrates for semiconducting circuits.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services