Ceramic manufacturing is the process used to sinter and fabricate ceramic materials into non-metal parts. The term “ceramics” refers to a wide range of products and materials used for an equally wide variety of applications, from commercial uses to the aerospace industry. They may come in the form of powdered composites or semi-liquid inorganic materials. Read More…

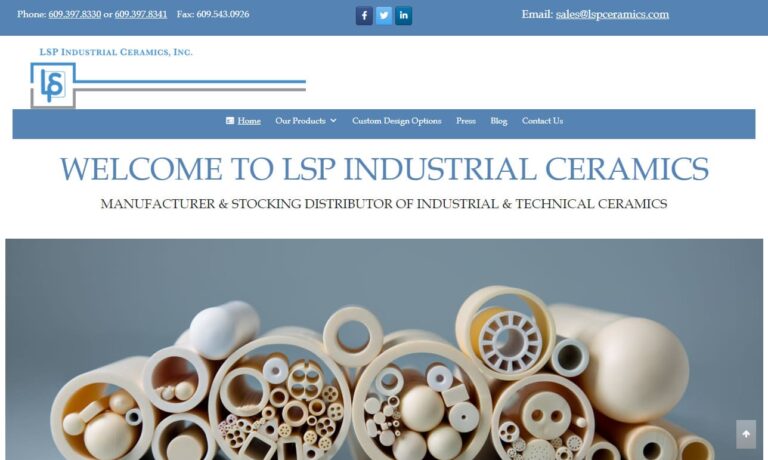

As a manufacturer and stocking distributor of industrial and technical ceramics, LSP carries the most diversified inventory of ceramic tubes, spacers, bushings, etc. in the industry.

C-Mac International manufactures custom advanced technical ceramic solutions. Our specialties are Zirconia (MgO stabilized and Yttria stabilized), Alumina (90%, 96%, and 99.5% purity), and Tungsten Carbide (Cobalt and Nickel Binder). We also work with steatite, cordierite, silicon nitride, ceramic crucibles, and crushable ceramics. We prioritize customer needs - we have a 48-hour delivery on...

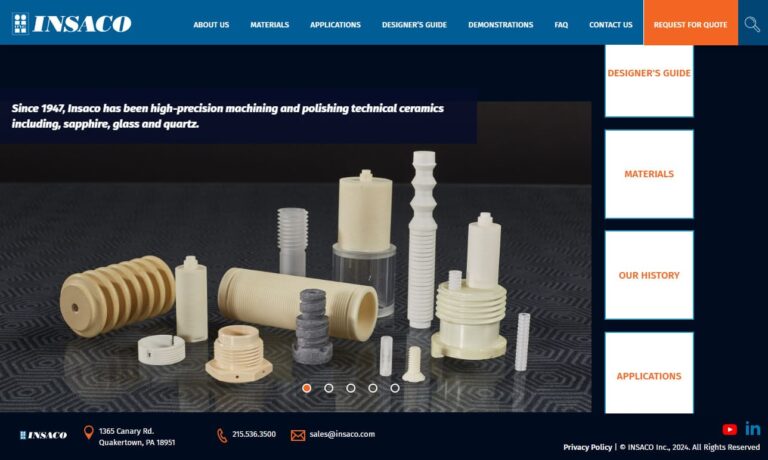

Insaco provides custom grinding and machining services to fabricate precision parts from sapphire, quartz, and most technical ceramics including alumina, zirconia, silicon carbide, silicon nitride, aluminum nitride, and others.

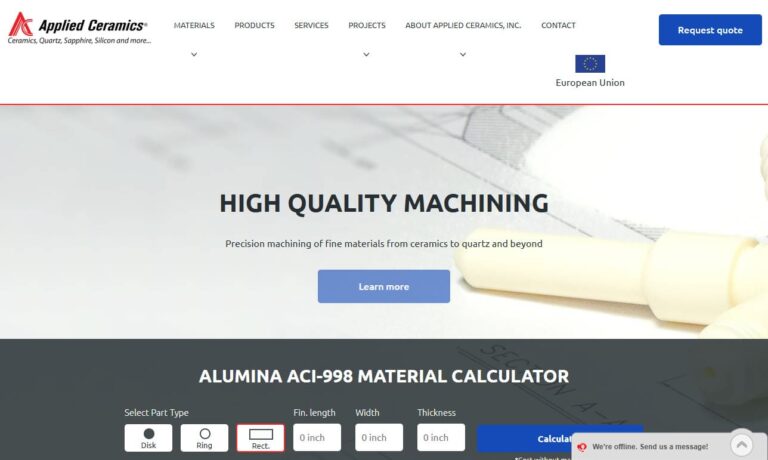

Applied Ceramics is a fabricator of custom-made ceramic parts designed for semiconductor, solar, fuel cell, oil drilling, nuclear, and numerous other industries. Materials include ACI-995 Alumina, Zirconia, and more. Our extensive experience with precision designs supported by our team of specialists ensures that our customers have the ideal solution to meet the needs of their application. To get ...

Aremco is a leader in the custom formulation of advanced industrial materials including technical ceramics. Offering many capabilities for a broad range of machinable & dense ceramic materials, Aremco serves aerospace, automotive, electrical, electronics, heat treating, metallurgical, petrochemical & plastics applications with superior finished ceramic parts. 100’s of standard industrial...

GBC Advanced Materials is a leading provider of advanced ceramic solutions, specializing in a wide range of iso-pressing techniques, green machining, sintering, extrusion, and CNC grinding. With a focus on innovation, precision, and quality, we offer comprehensive capabilities to meet the diverse needs of industries worldwide.

More Ceramic Manufacturing Companies

What is Ceramic Machining?

Ceramic machining is a precision manufacturing process that transforms raw ceramic materials into finished or near-net shape products using a combination of advanced techniques such as mixing, forming, firing, and precision finishing. Engineered ceramics—also known as technical ceramics, advanced ceramics, or industrial ceramics—are renowned for their exceptional material properties, including high-temperature resistance, extreme hardness, wear resistance, electrical insulation, and a robust crystalline structure. These unique attributes make ceramic machining a vital process for industries that require complex components capable of withstanding harsh environments and demanding mechanical, thermal, or chemical conditions.

Are you wondering how ceramics are machined to tight tolerances? Or which industries rely most on advanced ceramic components? Use the in-depth resources on our site to explore specific applications, compare manufacturing techniques, and find suppliers who can deliver the precise ceramic parts you need.

Read a deep dive into Ceramic Machining…

Ceramic Applications

Ceramic manufacturing is foundational to producing a diverse range of industrial and commercial products for high-impact, high-value applications. Ceramics are critical in sectors such as military and defense (armor, missile cones, ballistic plates), aerospace (thermal protection systems, engine parts), construction (tiles, bricks), automotive (oxygen sensors, engine components), refractory (kiln linings), power generation (insulators, fuel cells), and chemical processing (corrosion-resistant linings, membranes). Even the food processing industry benefits from non-reactive ceramic surfaces and tools.

- Electronics: Ceramics are integral to circuit boards, capacitors, insulators, substrates, and piezoelectric devices.

- Medical/Biomedical: Used for prosthetics, dental implants, bone replacements, and bioactive coatings, leveraging biocompatibility and inertness.

- Environmental: Ceramic membranes and catalysts are crucial in water purification, emissions control, and pollution mitigation.

Curious about how ceramics improve product durability or manufacturing efficiency? Or want to find the best ceramic solutions for your industry? Explore our application guides and case studies to discover the right ceramic materials and processes for your project.

Products Produced from Ceramic Manufacturing

Ceramic products can be categorized into four main groups:

- Structural Ceramics: Includes building materials such as bricks, tiles, and pipes, valued for their compressive strength and longevity in construction and infrastructure projects.

- Refractories: High-temperature resistant linings (e.g., kiln linings, crucibles), used in furnaces, reactors, and incinerators.

- Whitewares: Decorative and functional pottery, bone china, porcelain, and sanitary ware, prized for aesthetics and non-porous surfaces.

- Technical Ceramics (Advanced/Engineering Ceramics): Engineered for specialized performance, including wear parts, electrical insulators, substrates, sensors, and more.

Advanced ceramics represent the cutting edge of materials science—offering exceptional insulation, thermal shock resistance, chemical and corrosion resistance, and structural strength. These engineered ceramics find essential use in:

- Nuclear power: Fuel pellets, control rods, and shielding.

- Aerospace: Thermal tiles, jet engine parts, and sensors.

- Biomedical devices: Bone and dental implants, prosthetic joints, and surgical tools.

- Military applications: Body armor, missile cones, and electronics casings.

- Automotive: Oxygen sensors, spark plug insulators, and high-performance bearings.

- Electronics and electrical engineering: Capacitors, insulators, superconductors, and piezoelectric elements.

Additionally, ceramic coatings enhance component lifespan by reducing chemical corrosion and providing thermal barriers for engine components. Chemical and environmental ceramics—such as catalytic substrates, membranes, and fibers—help absorb toxins, reduce pollution, and purify water. Common industrial ceramic products include precision bearings, balls, rods, bushings, and custom insulators for electrical assemblies.

Searching for application-specific ceramic products? Use our directory and buyer’s guides to find manufacturers specializing in your required industry or product type.

History of Ceramics

Ceramic technology has evolved over millennia. Ancient civilizations, such as the Egyptians and Babylonians, used ceramics extensively for both functional and decorative purposes. The Ishtar Gate of Babylon featured iconic ceramic tiles, while Egyptians utilized ceramic bricks as early as the 4th millennium BC. The use of clay as a ceramic material dates back to prehistory—yet the industrialization of ceramics began in the 18th century.

Key milestones include:

- 1709: Abraham Darby’s use of coke and clay in smelting, marking the beginnings of ceramic engineering.

- 1759: Josiah Wedgwood established one of the first large-scale ceramics factories in England, revolutionizing ceramic production.

- 1880: Pierre and Jacques Curie discovered piezoelectricity, enabling the rise of electroceramics (piezoelectric ceramics).

- 1888: Carl Josef Bayer developed the Bayer process for extracting aluminum from bauxite, reducing costs and expanding ceramic material availability.

- 1893: E.G. Acheson invented a method for producing silicon carbide, a super-hard ceramic material.

- Early 20th Century: World Wars I and II accelerated the development of advanced ceramic materials and forming techniques, leading to innovations in armor, safety equipment, and high-performance industrial components.

- Recent Decades: Breakthroughs in materials such as hydroxyapatite (for biomedical uses), ceramic magnets (e.g., for maglev trains), and heat-resistant ceramics for space exploration. Ongoing research aims to improve ceramic molding, achieve higher precision tolerances, and develop new formulations for extreme environments.

Want to understand how modern ceramics differ from traditional pottery? Or which innovations are shaping the future of ceramic engineering? Browse our knowledge base for insights into past and emerging ceramic technologies.

Ceramic Materials Process

Industrial ceramic manufacturing is a multi-step process involving the transformation of raw minerals into high-performance engineered components. Key steps include:

- Milling: Raw materials are reduced in size through crushing, grinding, and milling to prepare for subsequent processing.

- Batching: Accurate measurement and mixing of materials, including additives, to achieve desired ceramic properties.

- Mixing: Combining all ingredients—often with water or other liquids—to form uniform slurries or doughs suitable for forming.

- Forming: Techniques such as slip casting, pressing (uniaxial, isostatic, or hot), extrusion, or injection molding shape the ceramic into the desired geometry.

- Drying: Carefully controlled drying solidifies the formed part and prevents defects during firing.

- Sintering: High-temperature firing densifies and strengthens the “greenware” (unfired ceramic), promoting the formation of a robust crystal structure and strong atomic bonds.

- Finishing: Secondary processes—such as machining, grinding, glazing, polishing, or laser cutting—achieve final tolerances and surface finishes.

Explore our step-by-step ceramic manufacturing guides for detailed information on each process, equipment options, and troubleshooting tips to optimize your production line.

Key Ceramic Materials and Their Applications

Alumina Ceramic

Alumina ceramic (aluminum oxide ceramics) is renowned for its outstanding chemical stability, high hardness, and superior electrical insulation. Formed via injection molding or isostatic pressing, alumina ceramics are widely used in electronics (substrates, insulators), medical devices (prosthetics, dental implants), wear parts, and high-temperature components. Their exceptional corrosion resistance and dielectric strength make them indispensable in semiconductor manufacturing, aerospace, and energy sectors.

Aluminum Nitride

Aluminum nitride ceramics are synthetic materials with high thermal conductivity and excellent dielectric properties, making them ideal for microelectronics, LED lighting substrates, and heat sinks. Their stability at temperatures above 3632°F (2000°C) ensures performance in power electronics, optoelectronics, and renewable energy applications.

Steatite Ceramics

Manufactured primarily from magnesium silicate, steatite ceramics excel as electrical insulators in thermostats, connectors, and switchgear. Their robust strength and durability also support use in both commercial and residential electrical systems, where long service life and reliability are critical.

Zirconia Ceramics

Zirconia (zirconium oxide) ceramics offer exceptional fracture toughness, wear resistance, and chemical inertness. Common uses include dental crowns, cutting blades, fuel cell components, and high-performance automotive sensors. Their ability to withstand mechanical stress and corrosion makes them a top choice for precision engineering applications.

Silicon Carbide Ceramics

Silicon carbide ceramics, produced by sintering fine SiC powder, are valued for their extreme hardness, thermal conductivity, and resistance to thermal shock. Applications include automotive brakes and clutches, mechanical seals, semiconductor process equipment, and armor plating.

Silicon Nitride

Comprised of silicon and nitrogen, silicon nitride ceramics deliver superior creep resistance, thermal shock resistance, and mechanical strength at elevated temperatures. Typical uses are found in turbine blades, ball bearings, cutting tools, and welding nozzles.

Mullite Ceramics

Mullite, a rare aluminum silicate mineral, is prized for its high-temperature stability and low thermal conductivity. Mullite ceramics are essential in refractory linings, kiln furniture, and applications where thermal expansion must be minimized. While more expensive due to raw material scarcity, they offer unique benefits for demanding environments.

Ceramic Glass

Ceramic glass, distinct from standard glass, withstands high temperatures without warping or breaking. It is used in fireplace doors, wood-burning stove panels, and laboratory equipment requiring optical clarity and thermal stability.

Clay

While industrial ceramics rarely use pure clay, traditional ceramics (bone china, porcelain, earthenware, stoneware) rely on its plasticity and firing characteristics for everyday products and decorative items.

Detailed Ceramic Manufacturing Processes

Each step in ceramic manufacturing can impact the final product’s strength, precision, and performance. Here’s a closer look at critical stages:

Forming Techniques

- Slip Casting: Ideal for thin-walled, complex shapes, widely used in sanitary ware and technical ceramics.

- Pressing (uniaxial & isostatic): Hot pressing and hot isostatic pressing are preferred for advanced ceramics to achieve high density and precise shapes.

- Extrusion: Cost-effective for producing pipes, tubes, and other long, uniform profiles.

- Injection Molding: Enables intricate shapes and high production rates for small components.

Sintering and Finishing

- Sintering: High-temperature firing promotes densification and solid-state bonding, crucial for strength and integrity.

- Finishing: Diamond grinding, lapping, and polishing achieve tight tolerances and smooth surfaces required in high-performance applications.

Looking for best practices in ceramic forming or finishing? Our technical articles and video tutorials can help you optimize your production workflow.

Alumina Ceramic Production

The journey from bauxite ore to precision-engineered alumina ceramics involves:

- Bauxite Processing: Bauxite is ground, washed, and dissolved in caustic soda and lime, then heated under pressure in a digester to extract aluminum compounds.

- Separation and Filtration: Impurities are removed via settling tanks and filtration, isolating the aluminum-rich solution.

- Crystallization: Alumina hydrate crystallizes around seed particles in precipitators, and is filtered to recover purified alumina.

- Calcination: Alumina hydrate is heated in rotary kilns, removing water and producing high-purity alumina powder for ceramic processing.

Strict control of temperature, pressure, and chemical composition ensures premium-quality alumina ceramics, suitable for demanding industries such as electronics, automotive, and aerospace.

Mixing of Alumina Powder

Mixing techniques directly influence ceramic quality:

- Spray-Dried Powder: Granulated for pressing; binders enhance strength and compactability.

- Aqueous Slip: Fluid slurries enable casting of intricate shapes and thin sections.

- Ceramic Dough Feedstock: Malleable blends allow extrusion or manual shaping for custom parts.

Proper selection and control of mixing methods ensure optimal consistency, density, and performance for the intended application.

Alumina Ceramic Forming Processes

Forming is tailored to application needs:

- Extrusion: Shaping dough feedstock under pressure into pipes, rods, or profiles.

- Isostatic Pressing: Uniform pressure (wet or dry) compacts powder into complex, high-density forms.

- Slip Casting: Aqueous slurries poured into molds yield thin-walled, detailed components.

- Uniaxial Pressing: Compression along one axis forms uniform, strong parts.

- Electrophoretic Deposition (EPD): Electrostatic forces deposit ceramic particles for precise coatings or specialized shapes.

Need advice on choosing the right forming technique for your ceramic project? Compare methods in our process comparison charts and consult with our experts for tailored recommendations.

Alumina Ceramic Finishing Processes

Post-sintering operations refine dimensional accuracy and surface integrity:

- Diamond Grinding: Achieves precise tolerances and smooth finishes for high-wear applications.

- Cutting, Honing, Lapping, Polishing: Various diamond-based processes deliver the final performance characteristics required for specialized components.

Explore our finishing equipment and tooling guides to identify the best solutions for your products.

Ceramic Design

Effective ceramic design starts with a clear understanding of application requirements, material properties, and production capabilities. Key considerations include:

- Material Selection: Choose from alumina, zirconia, silicon carbide, and other advanced ceramics based on thermal, mechanical, or electrical needs.

- Geometry and Wall Thickness: Optimize for strength, weight, and manufacturability.

- Forming and Finishing Processes: Align design features with available manufacturing technologies for cost-efficiency and performance.

- Customization: Tailor product dimensions, surface finishes, and tolerances to end-use specifications.

Download our ceramic design checklist to ensure your project meets all performance and production goals.

Machinery Used in Ceramic Manufacturing

Modern ceramic manufacturing relies on sophisticated equipment and automation to improve quality, efficiency, and scalability. Common tools include:

- Ovens/Kilns: For sintering and firing at precise temperatures.

- Molds: Silicone, metal, or custom-designed for forming complex shapes.

- Extrusion and Injection Molding Machines: For mass production of consistent parts.

- Grinding and Finishing Equipment: Diamond tools for post-processing.

- Computer-Aided Design (CAD) and Simulation Software: For prototyping, blueprint development, and process optimization.

Considering automation upgrades or custom tooling for your ceramic production line? Check out our equipment reviews and vendor comparisons to make an informed investment.

Ceramic Benefits

Ceramics offer substantial advantages over metals, polymers, and traditional materials, including:

- High Performance in Extreme Environments: Withstand heat, corrosion, and wear where metals or plastics would fail.

- Longevity and Reliability: Outlast conventional materials in demanding applications, reducing maintenance and replacement costs.

- Lightweight Yet Strong: Enable weight reduction without sacrificing durability—vital for aerospace and automotive engineering.

- Electrical and Thermal Properties: Insulation, conduction, or superconductivity as required by the application.

- Environmental Benefits: Non-toxic, inert, and capable of filtering pollutants or purifying water.

- Customizability: Can be engineered for specific mechanical, thermal, or chemical needs.

Although initial costs may be higher, the lifecycle cost savings and performance gains of ceramic components can far outweigh those of alternatives. Advanced ceramics also support sustainability initiatives by enabling energy-efficient designs and reducing environmental impact.

Things to Consider Regarding Ceramics

If you’re evaluating ceramic manufacturing for your business, product line, or engineering application, it’s critical to select a reputable, experienced manufacturer. Here’s a step-by-step approach to guide your decision:

- Research Manufacturers: Use our curated directory of trusted ceramic suppliers and manufacturers, each vetted for quality, capability, and customer satisfaction.

- Define Your Requirements: Identify your specifications—material type, tolerances, production volume, certifications, and secondary processing needs.

- Shortlist and Compare: Select three or four companies that best match your criteria. Review their product portfolios, case studies, and client testimonials.

- Request Quotes and Samples: Contact manufacturers directly, share your technical drawings or application details, and ask for samples or prototypes.

- Evaluate Responses: Assess pricing, lead times, technical support, and flexibility in meeting custom requirements.

Need help choosing the right ceramic manufacturer? Or want to compare quotes for a specific project? Reach out via our platform or download our vendor evaluation checklist to streamline your selection process.

Ready to take the next step? Browse our full list of Ceramic Manufacturing Companies and connect with suppliers who can deliver high-quality ceramic solutions tailored to your needs.

What is ceramic machining?

Ceramic machining is a precision manufacturing process that transforms raw ceramic materials into finished or near-net shape products using techniques such as mixing, forming, firing, and precision finishing. This process is essential for producing components that require high-temperature resistance, hardness, wear resistance, and electrical insulation for demanding industrial applications.

Which industries use ceramic components the most?

Ceramic components are critical in industries such as military and defense, aerospace, construction, automotive, power generation, chemical processing, electronics, medical/biomedical, and environmental sectors. Their unique properties make them vital in applications that demand high strength, corrosion resistance, and performance in extreme environments.

What are the main types of ceramic products?

Ceramic products are categorized into structural ceramics (such as bricks and tiles), refractories (e.g. kiln linings, crucibles), whitewares (e.g. porcelain, bone china), and technical or advanced ceramics (such as electrical insulators, wear parts, and sensors).

What is the typical ceramic manufacturing process?

The ceramic manufacturing process generally involves milling raw materials, batching and mixing them, forming the desired shapes through casting or pressing, drying, firing or sintering to strengthen the product, and finishing with machining or polishing to achieve precise tolerances and surface quality.

Which materials are most common in advanced ceramic manufacturing?

Common advanced ceramic materials include alumina (aluminum oxide), aluminum nitride, steatite, zirconia, silicon carbide, silicon nitride, mullite, and ceramic glass. Each offers specialized properties such as high hardness, thermal conductivity, dielectric strength, or resistance to corrosion and wear.

What benefits do ceramics offer over metals and plastics?

Ceramics provide high performance in extreme environments, outstanding longevity, light weight combined with strength, tailored electrical and thermal properties, and environmental benefits such as non-toxicity and the ability to filter pollutants more effectively than many metals or plastics.

What factors should you consider when choosing a ceramic manufacturer?

When selecting a ceramic manufacturer, consider their experience, range of materials and processes offered, ability to meet your technical requirements, product quality, production volume capability, certifications, and responsiveness to your custom needs. Comparing quotes, samples, and technical support is highly recommended.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services