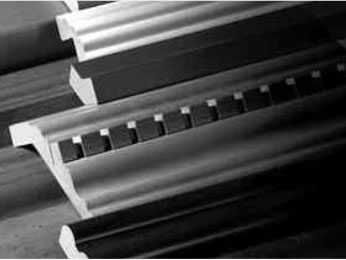

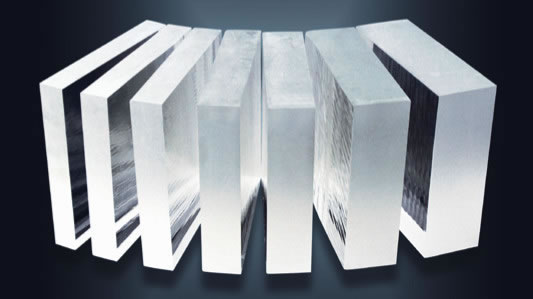

Ceramic is a hard material that is used for a wide variety of applications. In many industries, ceramics are used to make heating elements, computer parts, circuitry, pipes, decorative objects, and much more. In order to form ceramics into usable shapes they have to be ground down. Ceramic grinding requires a series of specialized tools depending on the type of project and what shape the final ceramic will have. In addition to ceramics, most ceramic grinding companies can also grind materials like aluminum oxide, carbon, ferrite, mullite, porcelain, gemstones, silicone carbide, quartz, and many other solid and composite materials.

The seven most common forms of grinding include, precision grinding, ceramic polishing, secondary machining, lapping, ultrasonic drilling, ultrasonic milling, and diamond slicing. It is rare for a company to require specialized grinding outside of these basic grinding procedures. Using one or more of these grinding techniques, a company can create nearly any form of ceramic product imaginable.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services