Ceramic tubes are used in applications that require a material that can resist high temperatures, electrical currents, erosion, impact and other hazards. Fuses, pump systems, degassers, furnaces and other equipment and components that operate under demanding conditions often involve the use of ceramic tubes. Read More…

As a manufacturer and stocking distributor of industrial and technical ceramics, LSP carries the most diversified inventory of ceramic tubes, spacers, bushings, etc. in the industry.

C-Mac International manufactures custom advanced technical ceramic solutions. Our specialties are Zirconia (MgO stabilized and Yttria stabilized), Alumina (90%, 96%, and 99.5% purity), and Tungsten Carbide (Cobalt and Nickel Binder). We also work with steatite, cordierite, silicon nitride, ceramic crucibles, and crushable ceramics. We prioritize customer needs - we have a 48-hour delivery on...

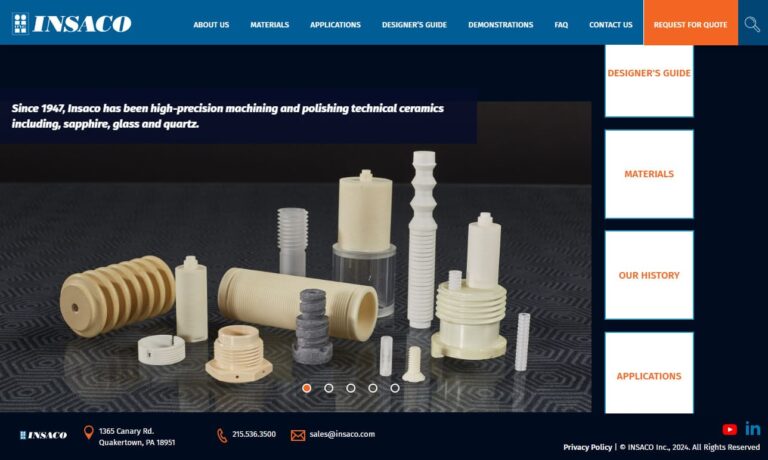

Insaco provides custom grinding and machining services to fabricate precision parts from sapphire, quartz, and most technical ceramics including alumina, zirconia, silicon carbide, silicon nitride, aluminum nitride, and others.

Applied Ceramics is a fabricator of custom-made ceramic parts designed for semiconductor, solar, fuel cell, oil drilling, nuclear, and numerous other industries. Materials include ACI-995 Alumina, Zirconia, and more. Our extensive experience with precision designs supported by our team of specialists ensures that our customers have the ideal solution to meet the needs of their application. To get ...

Aremco is a leader in the custom formulation of advanced industrial materials including technical ceramics. Offering many capabilities for a broad range of machinable & dense ceramic materials, Aremco serves aerospace, automotive, electrical, electronics, heat treating, metallurgical, petrochemical & plastics applications with superior finished ceramic parts. 100’s of standard industrial...

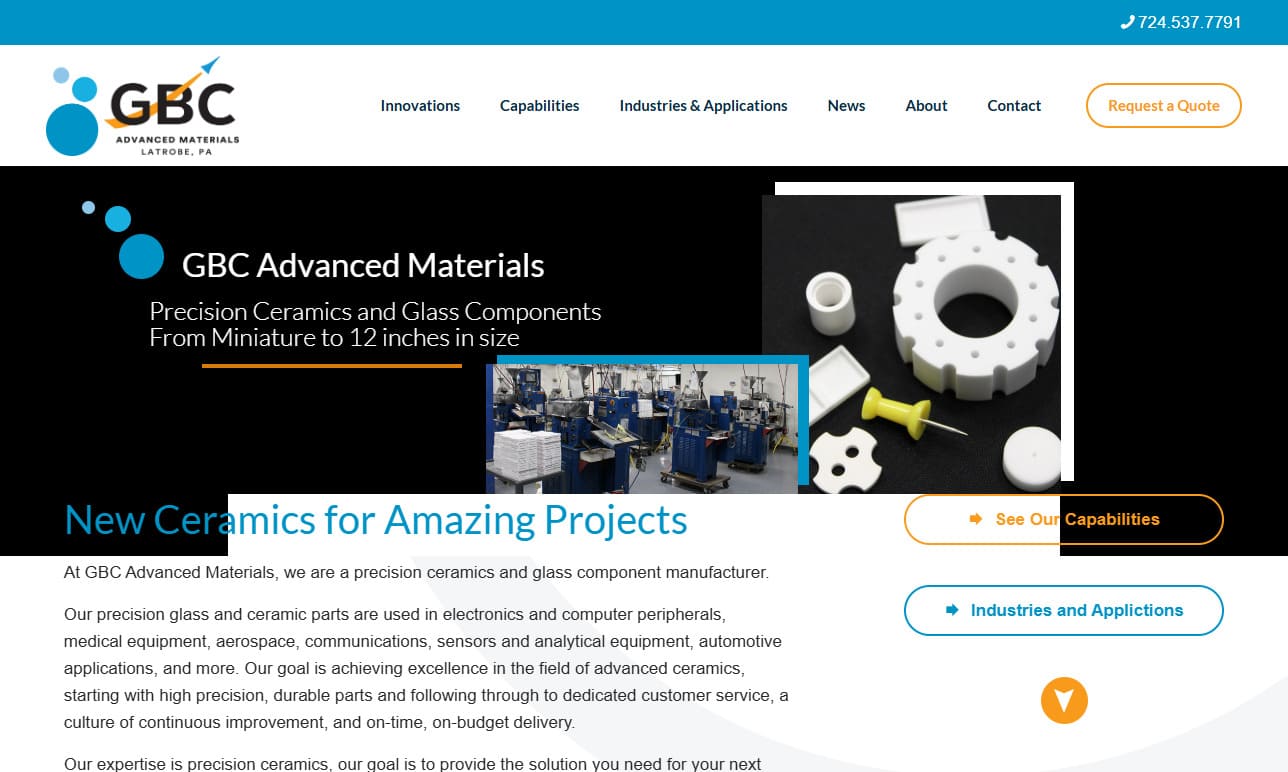

GBC Advanced Materials is a leading provider of advanced ceramic solutions, specializing in a wide range of iso-pressing techniques, green machining, sintering, extrusion, and CNC grinding. With a focus on innovation, precision, and quality, we offer comprehensive capabilities to meet the diverse needs of industries worldwide.

More Ceramic Tube Manufacturers

Ceramic tubes are resistant to thermal shock, which is the tendency of a material to become damaged when subject to dramatic changes in temperature. Their electrical non-conductivity can make them suitable as channels through which electrical wires can be passed.

Ceramics are very hard materials and are resistant to compressive force, however they are not resistant to shear force and can be damaged if subject to excessive angular force or tension. Ceramics are abrasion-resistant, which makes them good materials for the construction of tubes through which abrasive media pass.

Ceramic tubes can also be made porous; such ceramic tubing products are good candidates for certain specialized telecommunications tasks.

Ceramics have been in production for centuries; the earliest examples were simple, hand-formed pots and jars. Today, the basic concept of ceramic-making is similar; non-metal materials are still combined, heated and shaped to create a usable product.

The major differences between modern ceramics and early ceramics are the materials used and their applications. Depending on the intended application for a ceramic, any one of several raw materials can be chosen for ceramic product-making. Common examples include aluminum oxide, silicon carbide, zirconia and many others.

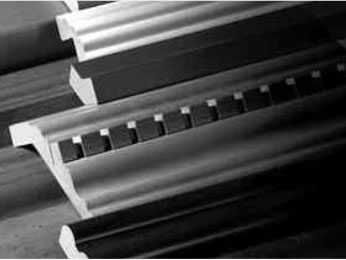

In the case of ceramic tubes, any material and construction method can be used. One of the most common tube construction methods is extrusion. Many other tube-shaped products are formed through the extrusion processes because it is highly efficient, continuous and produces uniform products.

The process begins with a collection of raw material suspended in a hopper over a conveyance channel. Once released into the channel, the material is heated to a molten state and forced through a die.

A die is a profile cut in a plate that is designed to give shape to materials that pass through it. The raw material passes through the die and takes its shape, emerging on the other side as newly-extruded tubing.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services