Ceramic bearings comprise ceramic rolling elements (balls) contained in ferrous (usually steel) inner and outer races. These bearings frequently function in hybrid capacities since they are made of several materials. Read More…

As a manufacturer and stocking distributor of industrial and technical ceramics, LSP carries the most diversified inventory of ceramic tubes, spacers, bushings, etc. in the industry.

C-Mac International manufactures custom advanced technical ceramic solutions. Our specialties are Zirconia (MgO stabilized and Yttria stabilized), Alumina (90%, 96%, and 99.5% purity), and Tungsten Carbide (Cobalt and Nickel Binder). We also work with steatite, cordierite, silicon nitride, ceramic crucibles, and crushable ceramics. We prioritize customer needs - we have a 48-hour delivery on...

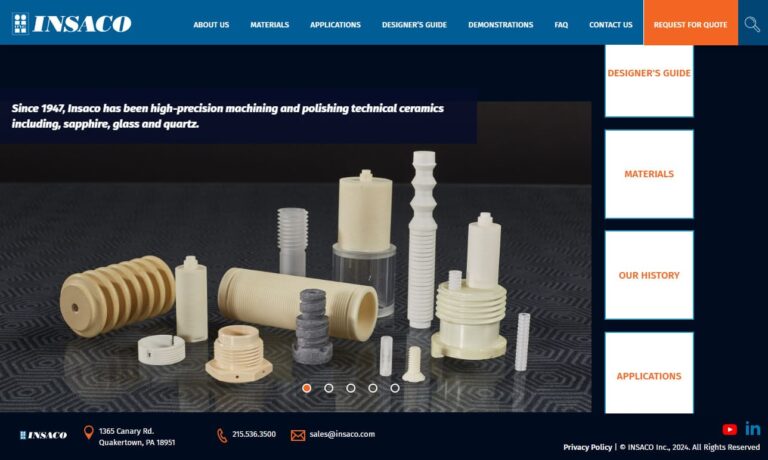

Insaco provides custom grinding and machining services to fabricate precision parts from sapphire, quartz, and most technical ceramics including alumina, zirconia, silicon carbide, silicon nitride, aluminum nitride, and others.

Applied Ceramics is a fabricator of custom-made ceramic parts designed for semiconductor, solar, fuel cell, oil drilling, nuclear, and numerous other industries. Materials include ACI-995 Alumina, Zirconia, and more. Our extensive experience with precision designs supported by our team of specialists ensures that our customers have the ideal solution to meet the needs of their application. To get ...

Aremco is a leader in the custom formulation of advanced industrial materials including technical ceramics. Offering many capabilities for a broad range of machinable & dense ceramic materials, Aremco serves aerospace, automotive, electrical, electronics, heat treating, metallurgical, petrochemical & plastics applications with superior finished ceramic parts. 100’s of standard industrial...

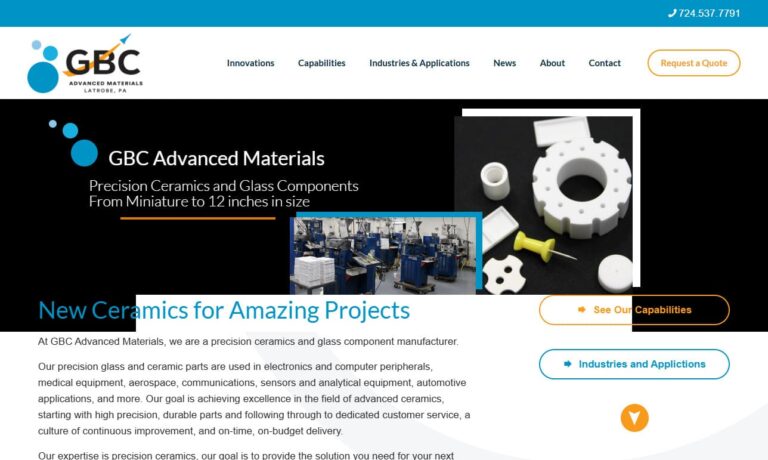

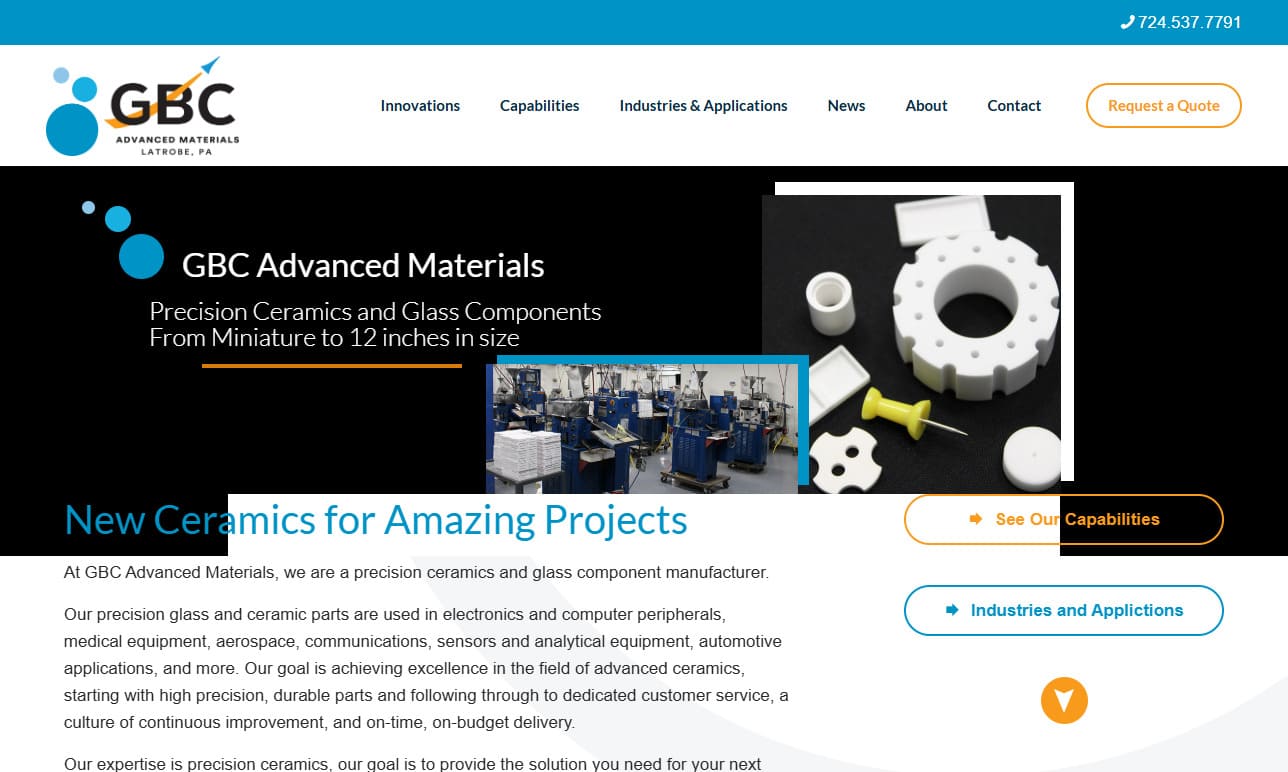

GBC Advanced Materials is a leading provider of advanced ceramic solutions, specializing in a wide range of iso-pressing techniques, green machining, sintering, extrusion, and CNC grinding. With a focus on innovation, precision, and quality, we offer comprehensive capabilities to meet the diverse needs of industries worldwide.

More Ceramic Bearing Manufacturers

What are Ceramic Bearings?

Ceramic bearings comprise ceramic rolling elements (balls) contained in ferrous (usually steel) inner and outer races. These bearings frequently function in hybrid capacities since they are made of several materials. Ceramic bearings are ceramic items that help two or more things move about one another. One example of a ceramic bearing is the metal slide mounted to a desk or dresser drawer that enables drawers to be pulled in and out.

All bearings, whether made of metal, ceramic, or another material, enable the movement of parts. There are numerous types of movement, and numerous bearing designs are available to support them.

Design of Ceramic Bearings

Ceramic bearings are available in a huge assortment of sizes and shapes, given that they are utilized in a wide range of items. For example, a ceramic bearing for rotating axles can take the form of a greased cylinder around which the axle rotates.

More complex bearings use a sequence of spherical, conic, or rod forms to permit the movement of two objects relative to one another. Each bearing construction material must be strong enough to support weight for lengthy periods, often with uneven distribution, without cracking.

They must also be abrasion-resistant because constant friction from movement can damage surfaces. In addition, they must be consistently formed to prevent movement obstructions and not corrode when exposed to the grease and oils required for smooth movement. Because they are durable and heat- and corrosion-resistant, several ceramics have proven to be the ideal bearing building materials.

Benefits of Using Ceramic Bearings

- Increased rigidity: The ceramic balls' improved smoothness, dimensional stability, and uniformity over steel ball bearings are the key causes of the decreased rolling resistance. These characteristics guarantee that applied loads are dispersed equally across all rolling parts. Additionally, compared to steel ball bearings with conventional seals and lubrication, ceramic materials have a much lower coefficient of friction (between 20 and 30 times lower). The lower friction results in faster rotational speeds and less rolling resistance.

- Their lighter weight further aids ceramic bearings' improved performance over steel bearings. Comparable steel bearings might weigh up to 40% more than ceramic alternatives. This decreased weight results in less centrifugal force being applied to the outer race when the bearing rotates. Ceramic bearings can operate up to 20–40% quicker than traditional steel bearings while requiring significantly less energy to maintain their speed due to the reduction in forces.

- Ceramic bearings are more durable than steel bearings because they are tougher. Studies show ceramic bearings can last five to twenty times longer than metal bearings. The ceramics' smoother surface greatly decreases the likelihood of bearing seizure with little to no lubrication. Furthermore, ceramic bearings can function in severe conditions due to their resistance to corrosion and deterioration. Finally, the rolling elements are not at risk of electrical erosion or pitting due to their electrical insulating qualities.

- Ceramic bearings are more durable than steel bearings because they are tougher. According to studies, ceramic bearings can last five to twenty times longer than metal bearings. The likelihood of bearing seizure with little to no lubrication is also greatly decreased by the ceramics' smoother surface. Furthermore, due to their resistance to corrosion and deterioration, ceramic bearings can function in severe conditions. Finally, due to their electrical insulating qualities, the rolling elements are not at risk of electrical erosion or pitting.

Applications of Ceramic Bearings

- Ceramic bearings are frequently used in aerospace for space exploration. They are perfect for satellites and spacecraft because of their small weight and compatibility with vacuums, which improves weight capacities for enhancing flight dynamics and acceleration. Furthermore, these bearings can function without lubricants like thick oils and greases, which often collect impurities that interfere with delicate electrical components.

- Most railroad traction motors have longer lives thanks to ceramic materials. ceramic bearings are also useful in chemical and mixing applications, particularly for preventing contamination.

- Ceramic bearings do not react with harsh chemicals or leach particles into delicate solutions since they are chemically inert. Ceramic bearings are the best choice for washdowns with highly acidic or alkaline chemical cleaning solutions because they are resistant to corrosion. Additionally, the absence of oil- and grease-based lubrication decreases the possibility of bacterial development and contamination.

Choosing the Right Ceramic Bearings Manufacturer

To make sure you have the most positive outcome when purchasing Ceramic Bearings from a Ceramic Bearings Manufacturer, it is important to compare at least 4 or 5 Companies using our list of Ceramic Bearings manufacturers. Each Ceramic Bearings Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Ceramic Bearings company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Ceramic Bearings companies with the same quote.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services