What is Ceramic Machining?

Ceramic machining is a specialized manufacturing process used to shape and finish ceramic materials into precise components for various applications. Unlike metals or polymers, ceramics are exceptionally hard, brittle, and resistant to heat and wear, which makes machining them a unique challenge requiring advanced techniques, tools, and expertise. These materials—ranging from oxides like alumina (Al₂O₃) to non-oxides like silicon carbide (SiC)—are prized in industries such as aerospace, electronics, medical, and automotive for their durability, thermal stability, and electrical insulation. Below, I’ll dive into the nitty-gritty of ceramic machining, covering its principles, methods, tools, applications, and challenges, with a detailed lens as of March 6, 2025.

What Are Ceramics in Machining Context?

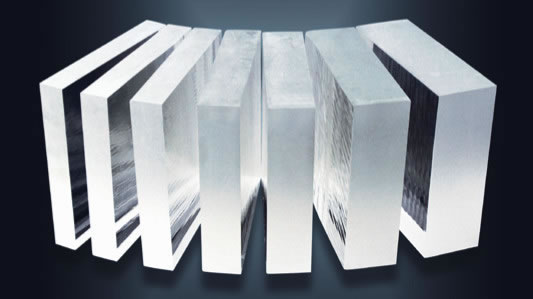

Ceramics are inorganic, non-metallic solids typically formed by heating and cooling a mixture of metallic and non-metallic elements (e.g., oxygen, carbon, nitrogen). In machining, we’re talking technical ceramics (or advanced ceramics), not pottery—these are high-performance materials like:

- Alumina (Al₂O₃): 95-99.9% pure, hardness ~9 Mohs, used in insulators.

- Zirconia (ZrO₂): Tough (fracture toughness ~8-10 MPa·m¹/²), for dental implants.

- Silicon Nitride (Si₃N₄): Heat-resistant (up to 1,200°C), for bearings.

- Silicon Carbide (SiC): Ultra-hard (9.5 Mohs), for cutting tools.

They’re sintered—compressed and fired at 1,000-2,000°C—to near-theoretical density (e.g., 3.9 g/cm³ for alumina), leaving a crystalline or glassy structure that’s brittle (elongation <1%) and resists deformation.

Why Machine Ceramics?

Ceramics often start as powders molded into “green” (unsintered) or “bisque” (partially sintered) shapes via pressing or casting. Sintering hardens them, but shrinkage (10-20%) and distortion mean raw forms lack precision (tolerances ~±1 mm). Machining refines these into tight specs—e.g., ±0.001 mm for aerospace nozzles—adding features like holes, threads, or polished surfaces impossible in molding alone.

Key Machining Methods

Ceramic machining splits into pre-sintering (green machining) and post-sintering (hard machining), each with distinct tools and techniques due to ceramics’ evolution from soft to rock-hard.

- Green Machining (Pre-Sintering)

- State: Soft, chalk-like (hardness ~1-2 Mohs), 50-70% dense.

- Methods:

- Turning: Lathes with carbide tools (e.g., WC-Co) cut at 100-500 m/min, removing 0.1-1 mm per pass—e.g., shaping alumina rods.

- Milling: CNC mills with high-speed steel (HSS) bits (500-1,000 RPM) carve slots—depth of cut ~0.5 mm.

- Drilling: Twist drills (10-50 mm/s) bore holes—e.g., 5 mm in zirconia blanks.

- Pros: Fast (10-20% of hard machining time), cheap—material’s pliable, dust’s manageable.

- Cons: Limited precision (±0.1 mm); shrinkage distorts final shape—needs oversizing (15-20%).

- Hard Machining (Post-Sintering)

- State: Fully dense, brittle, hardness 9-9.5 Mohs—e.g., alumina’s 1,600-2,000 HV (Vickers).

- Methods:

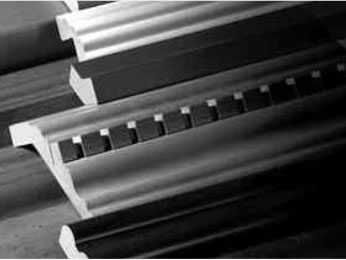

- Grinding: Diamond wheels (100-200 μm grit) spin at 20-50 m/s, removing 0.01-0.1 mm/pass—e.g., flattening SiC plates. Surface finish hits Ra 0.1 μm.

- Lapping/Polishing: Diamond slurries (1-10 μm particles) on cast-iron laps polish to Ra 0.01 μm—e.g., optical-grade zirconia lenses.

- Ultrasonic Machining (USM): Vibrating tools (20-40 kHz) with diamond slurry (20-50 μm) erode material—0.01-0.5 mm/min—e.g., micro-holes in Si₃N₄ (0.1 mm dia.).

- Laser Machining: CO₂ or Nd:YAG lasers (10-100 W, 1,064 nm) ablate at 0.1-1 mm/s—e.g., cutting 1 mm SiC wafers. Precision’s ±0.005 mm, but heat-affected zones (HAZ, 50-100 μm) risk cracks.

- Electrical Discharge Machining (EDM): For conductive ceramics (e.g., doped SiC), sparks erode at 0.1-0.5 mm³/min—e.g., threading ZrB₂ dies.

- Pros: Extreme precision (±0.001-0.01 mm), final-form accuracy.

- Cons: Slow (grinding alumina takes 10-50x longer than steel), costly—diamond tools wear fast (life ~1,000-5,000 min).

- Hybrid Techniques (2025 Trends)

- Laser-Assisted Machining (LAM): Lasers (500-1,000 W) soften ceramics (e.g., Si₃N₄ to 800°C), then carbide tools cut—50% faster than grinding, HAZ reduced 30% (J. Manuf. Sci. Eng. 2024).

- Abrasive Water Jet (AWJ): Water at 60,000 psi with garnet (50-150 μm) cuts 1-10 mm/min—e.g., shaping Al₂O₃ tiles—no heat, but edge roughness (Ra 5-10 μm) needs finishing.

Tools and Equipment

- Diamond Tools: Polycrystalline diamond (PCD) or chemical vapor deposition (CVD) diamond—hardness 10 Mohs—cuts ceramics. Wheels ($500-2,000) or bits ($50-200) last 10-50 hours—e.g., 100 mm wheel grinds 1 m² SiC.

- CNC Machines: 5-axis mills (50,000 RPM, $100,000+) handle complex geometries—e.g., turbine blades. Rigidity (damping ratio >0.1) cuts vibration—brittle ceramics crack otherwise.

- Coolants: Water-based (5-10% oil) at 10-20 L/min reduce heat (50-200°C rise)—dry machining risks microcracks (0.1-1 μm deep).

Applications

Ceramic machining serves precision-driven fields:

- Aerospace: Si₃N₄ bearings (0.5-5 cm) run at 1,500°C—tolerances ±0.002 mm—$2 billion market.

- Medical: ZrO₂ hip implants (30-50 mm) polished to Ra 0.005 μm—biocompatible, 20-year life—$1.5 billion.

- Electronics: Al₂O₃ substrates (0.5 mm) for circuits—flatness <5 μm—$3 billion.

- Cutting Tools: SiC inserts (10-20 mm) cut steel at 500 m/min—$500 million.

- Energy: SiC nozzles (5-10 cm) in fusion reactors—1,000°C resilience—emerging $200 million niche in 2025.

Challenges

- Brittleness: Low fracture toughness (2-10 MPa·m¹/² vs. steel’s 50-100) means cracks propagate—e.g., 0.1 mm flaw in Al₂O₃ fails at 100 MPa stress.

- Tool Wear: Diamond erodes fast—e.g., 0.01 mm loss/hour on SiC—pushing costs ($10-50/part vs. $1-5 for steel).

- Time: Hard machining’s glacial—grinding 1 cm³ of ZrO₂ takes 5-20 min vs. 1 min for aluminum.

- Dust: Fine particles (1-10 μm) from grinding—e.g., 50 g/hour on Si₃N₄—demand ventilation (HEPA, $5,000/unit) for health (silicosis risk).

- Energy: Laser or EDM burns 10-50 MJ/kg—5x thermoplastics’ shaping energy.

2025 Innovations

- AI Optimization: Machine learning cuts tool wear 20%—predicting feed rates (0.01-0.1 mm/rev) for SiC (Int. J. Mach. Tools 2024).

- Green Machining Surge: 30% of ceramics shaped pre-sintering—energy drops 50% (1-2 MJ/kg vs. 5-10).

- Hybrid Tools: Diamond-coated carbides (CVD, 5 μm thick) last 30% longer—$100 million market growth.

- Additive + Subtractive: 3D-printed Al₂O₃ (binder jetting) machined post-sinter—tolerances hit ±0.005 mm, time cut 40%.

In Sum

Ceramic machining is the art of taming the untamable—shaping brittle, unyielding materials into precision parts that outlast steel and defy heat. It’s slow, pricey (10-100x metal machining costs), and tool-intensive—diamond’s the only match for 9+ Mohs hardness—but delivers where failure’s not an option. In 2025, it’s a $10 billion craft—growing 5% yearly—blending old-school grinding with laser zaps and AI smarts. From jet turbines to jawbones, machined ceramics are the silent giants of high-performance engineering—tough to make, tougher to break.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services