The list goes on. Beyond this, advanced ceramics are used for aerospace, deep sea, medical, automotive, defense and energy industries. Read More…

As a manufacturer and stocking distributor of industrial and technical ceramics, LSP carries the most diversified inventory of ceramic tubes, spacers, bushings, etc. in the industry.

C-Mac International manufactures custom advanced technical ceramic solutions. Our specialties are Zirconia (MgO stabilized and Yttria stabilized), Alumina (90%, 96%, and 99.5% purity), and Tungsten Carbide (Cobalt and Nickel Binder). We also work with steatite, cordierite, silicon nitride, ceramic crucibles, and crushable ceramics. We prioritize customer needs - we have a 48-hour delivery on...

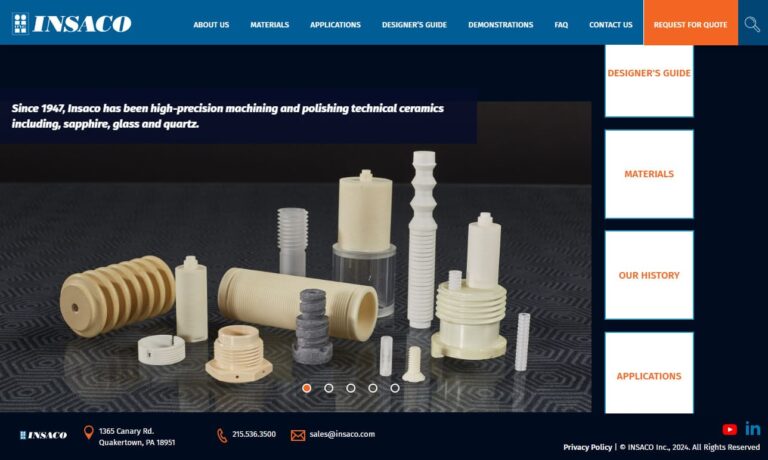

Insaco provides custom grinding and machining services to fabricate precision parts from sapphire, quartz, and most technical ceramics including alumina, zirconia, silicon carbide, silicon nitride, aluminum nitride, and others.

Applied Ceramics is a fabricator of custom-made ceramic parts designed for semiconductor, solar, fuel cell, oil drilling, nuclear, and numerous other industries. Materials include ACI-995 Alumina, Zirconia, and more. Our extensive experience with precision designs supported by our team of specialists ensures that our customers have the ideal solution to meet the needs of their application. To get ...

Aremco is a leader in the custom formulation of advanced industrial materials including technical ceramics. Offering many capabilities for a broad range of machinable & dense ceramic materials, Aremco serves aerospace, automotive, electrical, electronics, heat treating, metallurgical, petrochemical & plastics applications with superior finished ceramic parts. 100’s of standard industrial...

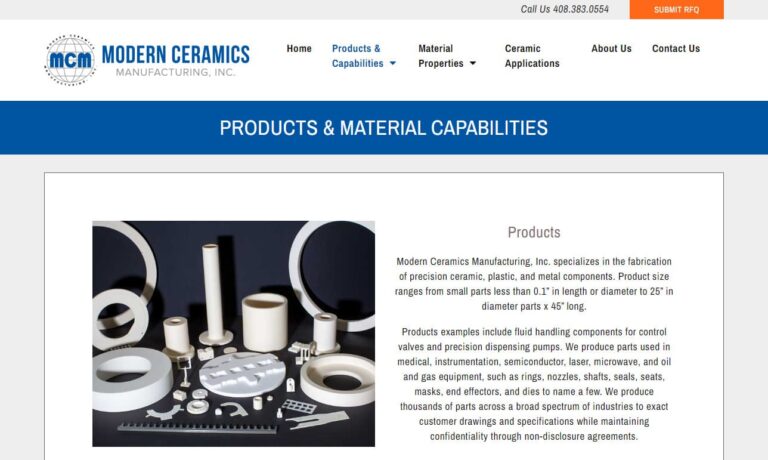

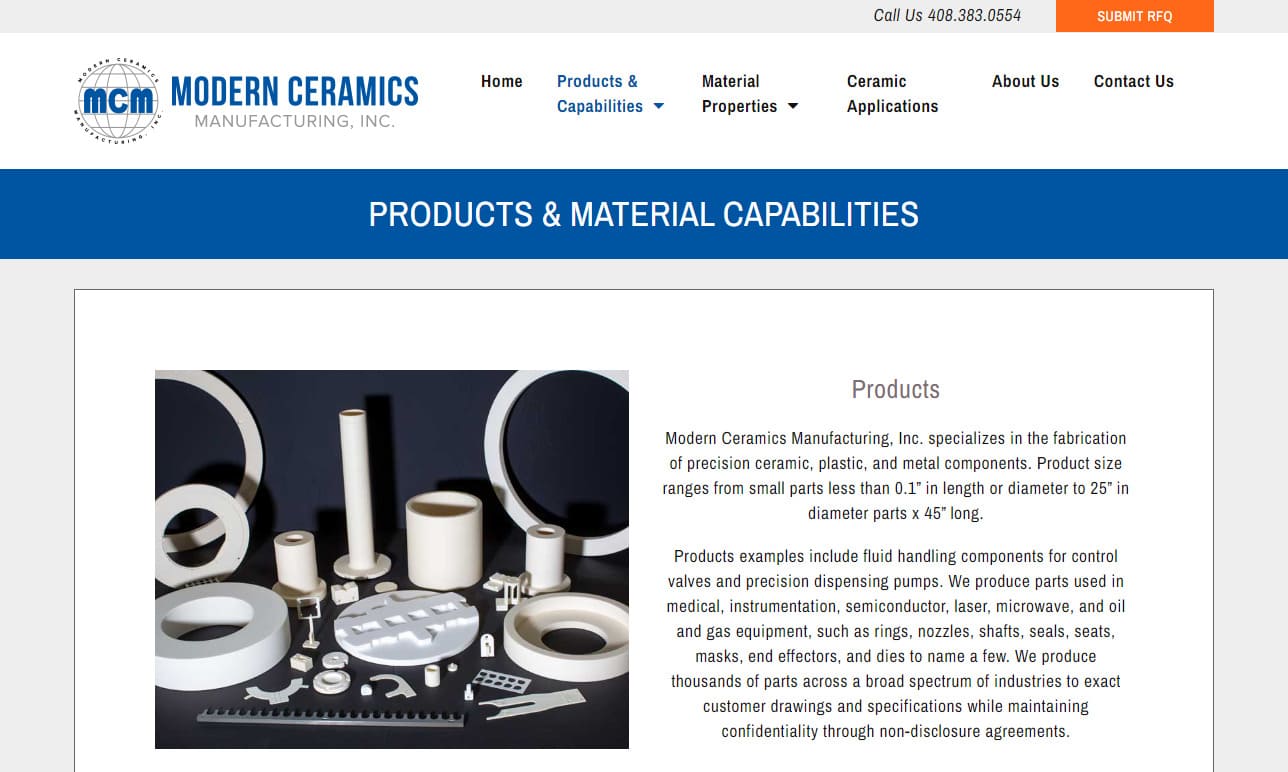

At Modern Ceramics Manufacturing, Inc., we specialize in delivering high-quality ceramic products tailored to meet the diverse needs of our clients. Our extensive range of offerings includes everything from industrial ceramics, such as tiles and bricks, to advanced technical ceramics used in specialized applications like electronics and aerospace.

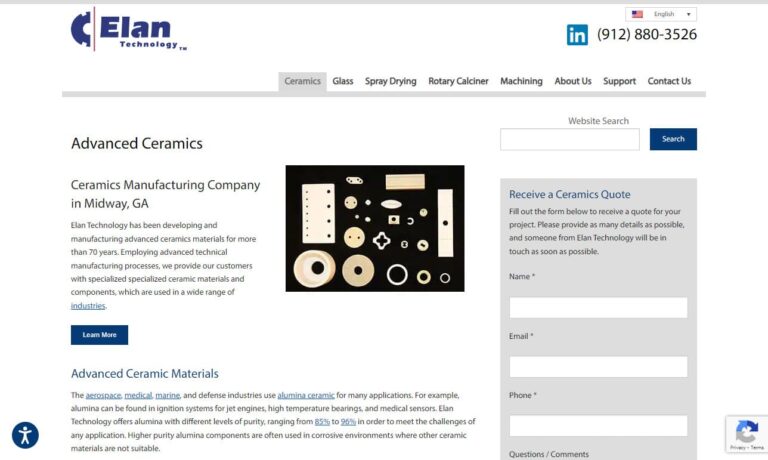

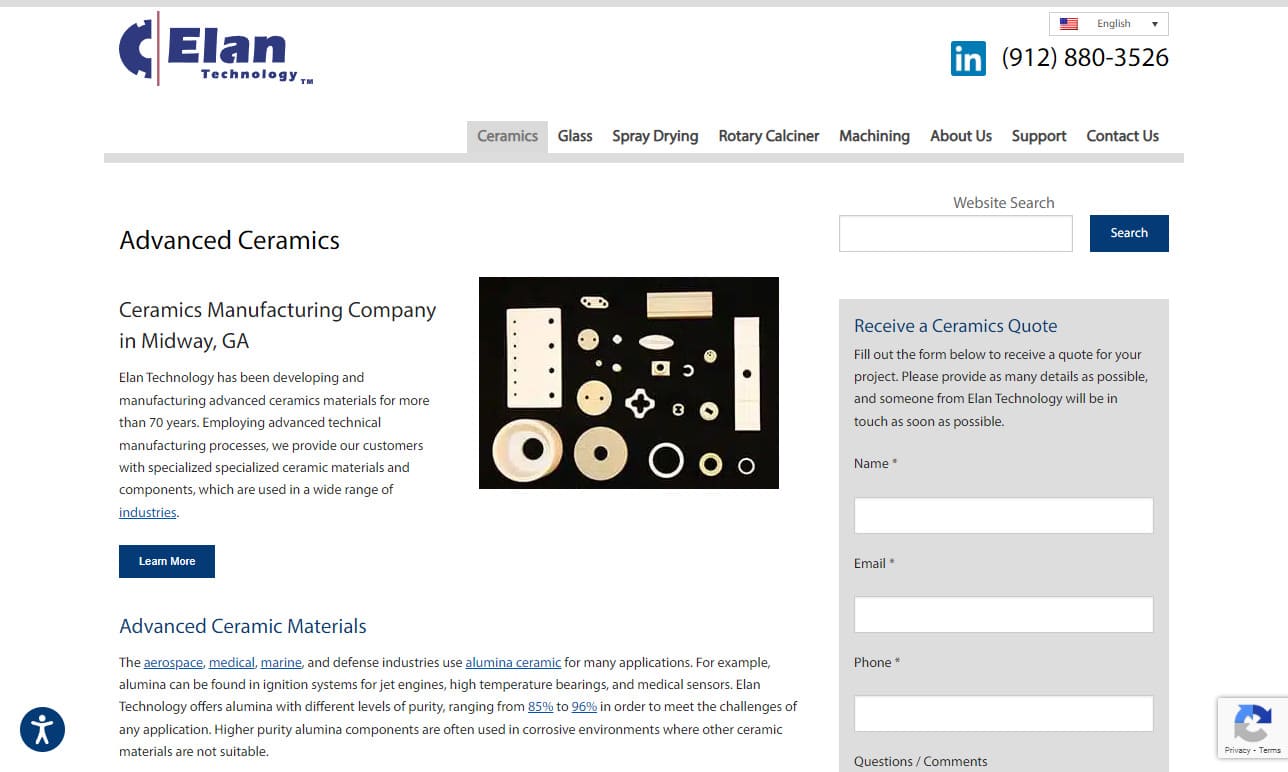

At Elan Technology, we pride ourselves on our expertise in ceramic manufacturing, where we bring together innovative processes and advanced materials to deliver exceptional products tailored to meet our customers' diverse needs. Our team works collaboratively to create high-performance ceramic components that serve various industries, including aerospace, medical, and electronics.

More Custom Ceramic Manufacturers

Manufacturers of such a truly versatile and far-reaching substance, that even contributes to NASA's space shuttles and to clean air technology, must offer many construction and material options to meet the variable needs of the market. These offerings are known as custom ceramics. The most commonly known ceramics include glass, pottery, cement and porcelain. However, simply as an inorganic, nonmetallic solid, the range of materials used in custom ceramics is much wider. Such materials include: aluminum oxide, aluminum nitride, silicon carbide, silicon nitride, zirconium oxide, boron carbide, single crystal silicon, yttria, magnesia and fused silica.

This vast store of solids is broken down into four main usage types: structural, refractory, whitewares and technical, which is also referred to as advanced, engineering, fine and special.

Structural ceramics include bricks, pipes and tiles. Refractory ceramics are used to make kiln linings, gas fire radiants and steel and glass making crucibles. Whitewares include tableware, cookware, sanitary products and pottery.

Technical ceramics include tiles used in the Space Shuttle program, biomedical implants, coatings of jet engine turbine blades, missile nose cones, mechanical bearings and the like.

When considering custom ceramics, a potential customer should consider what will best serve his or her needs, in terms of the ceramic's physical, thermal, mechanical and electrical properties.

Through material choice and construction, custom ceramics can be designed to address the challenges of extreme corrosion and wear, electrical conductivity or high temperature.

Physical properties to consider are: color, purity, bulk density and porosity. Mechanical properties to think about are a ceramic's hardness, flexural strength, compressive strength, elasticity and tensile strength.

Thermal properties to consider include heat resistance, thermal conductivity and expansion with heat. Finally, a potential customer must consider such electrical properties as dielectric strength, resistivity, dielectric constant and dielectric loss.

Other processes to consider include: near-net shaping, powder metallurgy, bisque processing, glazings, coatings, assembly, metalizing and plating.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services